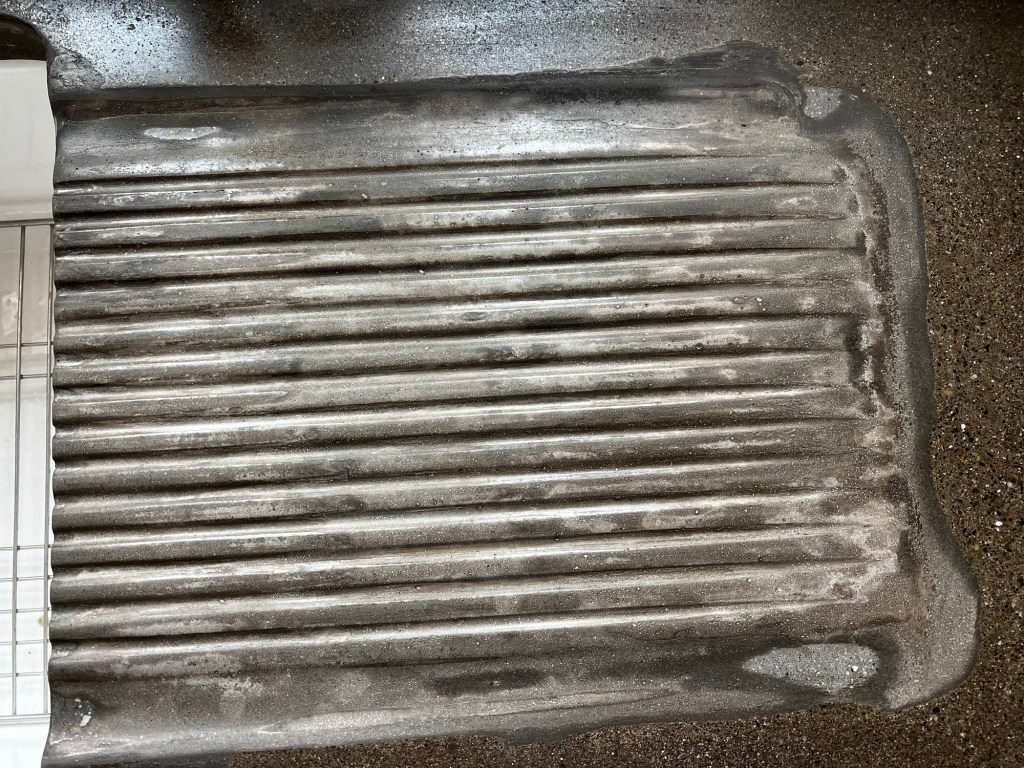

Let me start with the truth: I finally “finished” my concrete countertop drain board refurbish, and it’s blotchy as hell.

But here’s the thing—the shape is perfect. It looks exactly like a drain board should look. It’s just that after all the layers, all the different materials, and all my well-intentioned repair attempts, it’s ended up looking like a topographical map of somewhere with questionable weather patterns.

Attractive? Not particularly. Functional? Absolutely.

What I Learned the Hard Way

If you’re considering a similar project (and I hope you learn from my mistakes), here’s what I’d do differently:

Control the dust and commit to the repair. I should have actually cut out a clean shape to refill and feather properly. My edges were sloppy where materials overlapped, which contributed to the whole patchwork quilt aesthetic I wasn’t going for.

Match your materials from the start. In hindsight, I probably should have used the original concrete from our countertop and just sifted it out for a finer consistency. The color would have matched perfectly. Did I think of this? Yes. Did I want to buy a 60lb bag of concrete for a tiny patch? Absolutely not. Classic mistake.

Nail the first pour. Use a stiff mold with a hard surface on top for even pressure. Add weight and vibration if you can. And for the love of all that’s holy, use a release agent. That first pour is critical—you want it as close to perfect as possible so you’re only filling small holes afterward, not rebuilding entire sections.

Patience is a virtue I don’t have. Wait for it to dry before removing your mold. Wait for the concrete to fully cure before sanding. I know, I know—boring advice. But wet sanding takes off more material and makes it nearly impossible to blend different pours.

I used 5″ hook and loop diamond grinding disks left over from our original countertop project—starting at 50 grit for the big material takedown, then mostly working with 200 and 400 grit. I worked by hand with water, which was effective but also revealed how unevenly the different applications were curing.

When I switched to wet/dry sandpaper by hand, things got interesting. Dry sanding took off material faster but unevenly—probably because of my inconsistent material mix and impatient timing (see above about not waiting for full cure). Paradoxically, dry sanding with a coarser grit actually got the surface smoother, even though it removed less material overall. So I ended up using dry sanding for my final polish at around 400/600 grit.

Not-so-pro tip from a decidedly non-pro: I used a skinny dowel wrapped with sandpaper to work the drain channels of the board. It maintained the shape nicely without flattening out those grooves.

Go generous on your first application. Use extra material so it squeezes out from everywhere when you apply pressure with your form. This saves you from making multiple passes (and creating that lovely blotchy effect I achieved).

Materials That Actually Worked

I ended up using a combination of products, but honestly, I should have just started with Quikrete 5000 (which I think we used originally) and sifted it to a finer consistency.

Here’s what I actually used:

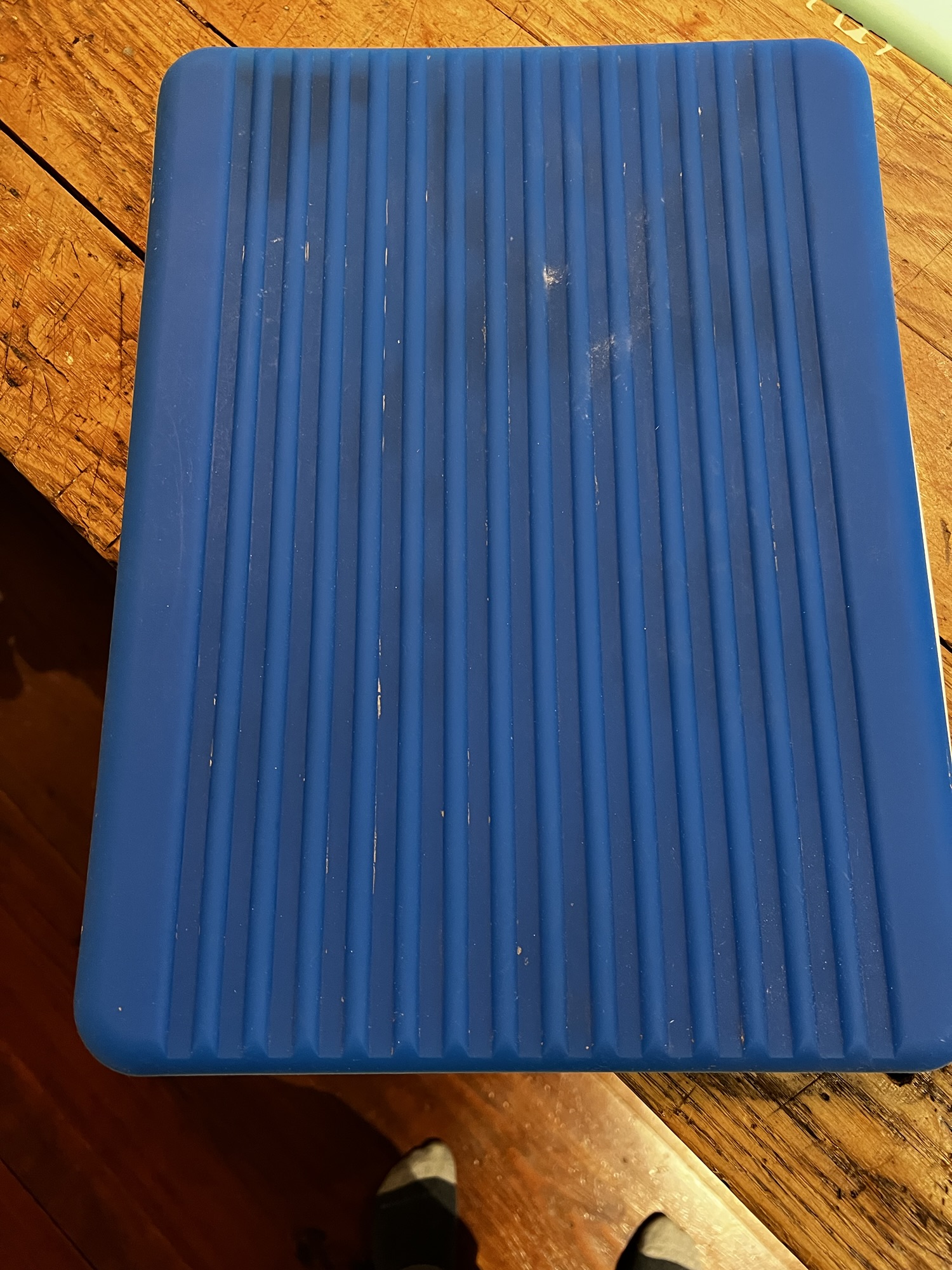

- Mold: Smooth-On Mold Max 60 (needs a solid surface on top for even pressure)

- Concrete Mix: A chaotic blend of sifted Top ‘n Bond Concrete Patcher, Henry Feather Finish, and Z Counter Patch

The Verdict

Is it finished? Not really. Is it close enough? Absolutely.

Sometimes “good enough” is the most honest conclusion to a DIY project. The drain board works, the shape is right, and sure, it looks like it’s been through some things—but haven’t we all?

Leave a comment