When a simple countertop repair turns into a three-week saga involving four molds, toe-damaging weights, and enough failed attempts to question your life choices.

The Origin Story: DIY Concrete Counters Circa 2010

Back in 2010, when YouTube had DIY videos but nothing like today’s endless stream of concrete countertop influencers, my wife and I decided to do something truly adventurous – pour our own concrete countertops. The information I found online was decent but limited, especially for our specific situation. Because, you know, why hire professionals when you can just wing it with your friend Marty and some questionable internet research?

Most of the instructions I found involved pouring the counters in a shop and then installing them. But Marty, my friend who was building most of the house, had the brilliant idea to pour them in place. And I’ll give credit where it’s due – this actually was genius since the kitchen wasn’t finished, and we could make all the mess we wanted without consequences. Well, immediate consequences anyway.

Armed with a rented concrete vibrator and a purchased wet sander with diamond discs (hello, messy nightmare), we poured our countertops. And honestly? They turned out pretty damn good for three people who had absolutely no idea what they were doing.

Except for one tiny detail.

The Drain Board of Doom

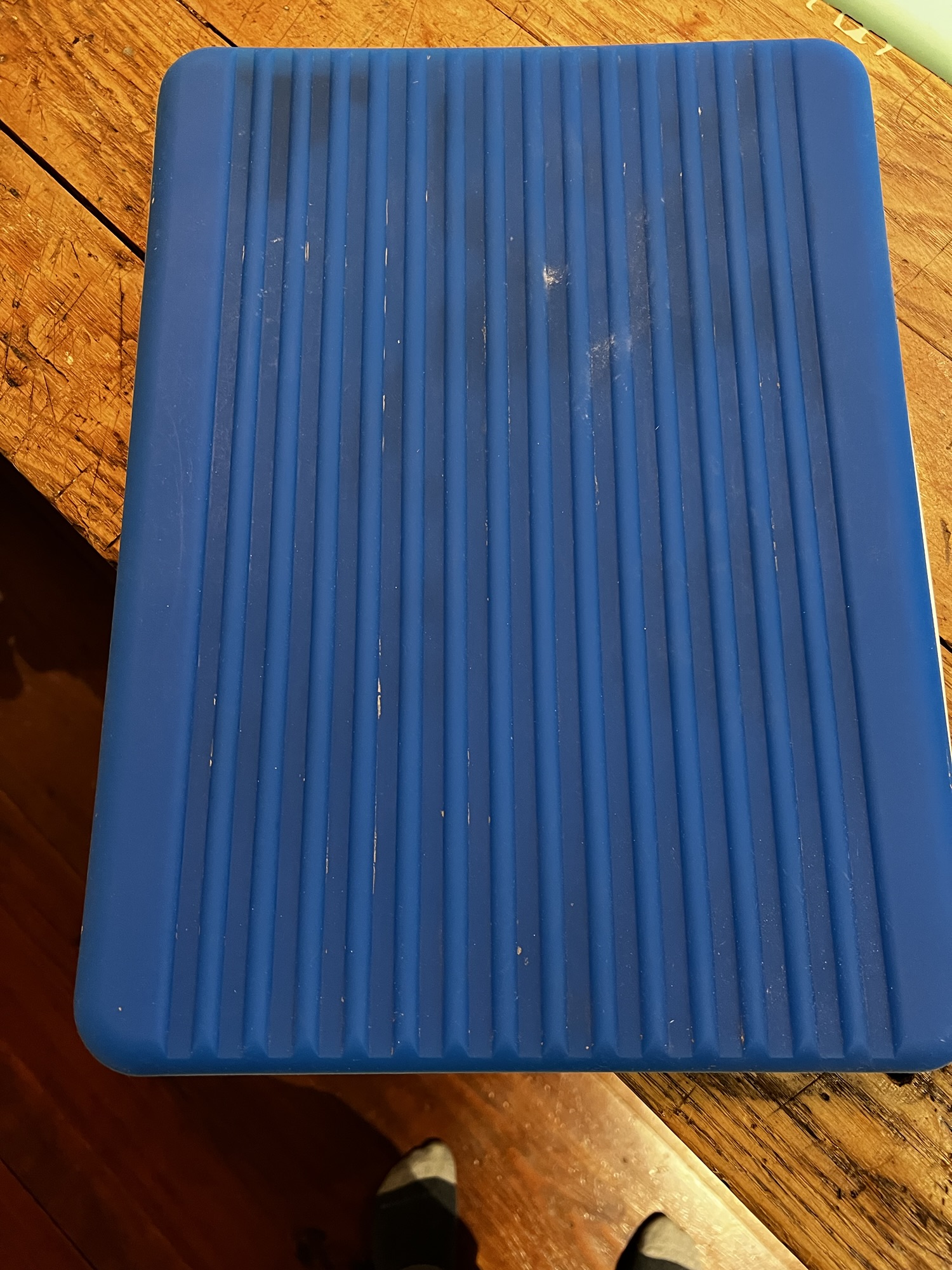

In a moment of design ambition, we decided to incorporate a drain board next to the sink. I found a plastic drain board to use as a mold. Marty, being Marty, cut the sides off and pressed the pattern into the wet concrete.

Spoiler alert: This would become the Achilles’ heel of our otherwise surprisingly successful concrete adventure.

Over time, that drain board area started to fail. Concrete slowly chipped away until we had rough, unsightly holes. We lived with this eyesore for years because, well, that’s what you do when you’re too stubborn to admit defeat.

But when it came time to refresh our kitchen cabinets (another DIY disaster story involving Killz primer and regular latex paint that I’ll save for another day), I decided it was time to face my drain board demons.

Attempt #1: The Soft Mold Saga

My first brilliant idea was to use Top ‘n Bond Concrete Patcher. The package said “for application thickness under 1/2 inch” which seemed perfect since I needed it to blend seamlessly with the existing counter.

Now I needed a mold. Because I’m the kind of person who hoards everything “just in case,” I still had the second dish drain I’d purchased as backup years ago. It was currently serving as a fancy container for loose bolts and miscellaneous hardware. Naturally.

But I couldn’t just use it directly as Marty had done originally (how DID he make that work?). So I decided to make a silicon rubber mold of the drain board. I ordered BBDINO Silicone Mold Making Kit and used some snowblower no-stick spray as a release agent because… why not?

The silicon mold turned out surprisingly well! Except it was wobbly and soft. But details, right?

I mixed my “perfect” concrete patch, applied it, pressed my “perfect” mold down, and waited for the magic to happen.

Several hours later, I peeled back the mold to reveal… a complete disaster. Half the material stuck to the mold, and because the mold was so soft, the material had a weird hump in it. Not exactly the pristine drain board I’d envisioned.

After some wet sanding, I discovered two problems:

- My mold was too soft

- The Top ‘n Bond was too coarse to feather to zero or smooth out enough

Back to the drawing board!

Attempt #2: The Carcinogenic Mold Experience

My research led me to two products: Henry Feather Finish and Z Counter Patch. I went with Henry Feather Finish because I could pick it up locally.

For the mold problem, I thought, “Aha! I need something solid like those resin tables!” I found Bondo liquid resin at the store. Perfect!

Except it wasn’t. This stuff smelled like cancer in a bottle. You know that smell – the one that makes you think “this is definitely taking years off my life”? Yeah, that one.

The resin cured into a significantly shrunken drain board mold. It was hard and solid as I wanted, but now too small to match my previous attempt. So naturally, I just decided to cover the original pour with the Henry Feather Finish and hoped the smaller mold wouldn’t matter.

This time, I used vegetable oil as a release agent because apparently I was just cycling through my kitchen and garage for solutions at this point.

The feather finish mixed beautifully. I pressed the mold into place, cleaned up the squeeze-out, and left it overnight.

The next morning, I lifted the mold to reveal… the same damn problem. The material still stuck to the mold. It was better, but still a mess.

The Henry Feather Finish was supposed to be dry-sandable, but it created so much dust I switched to wet sanding, which took up too much material. I couldn’t get it smooth no matter what grit I used.

Attempt #3: The “Non-Shrinking” Lie

I ordered Alumilite Amazing White Casting Resin Kit, advertised as “non-shrinking.” (Spoiler: that was a lie.)

My original drain board template was now warped from the Bondo resin, so I had to weigh it down to get the warps out while the new resin cured.

After a few hours, the material was hard and rigid as I wanted, but it still shrank a little. So much for “non-shrinking.”

For this attempt, I used petroleum jelly as the release agent and even sprayed water on the surface of the mold before pressing it down.

Oh, and remember that weight my son left on the living room floor? The one I stubbed my toe on? I had the brilliant idea to use it to press down on the mold. Surely the pressure would get rid of pockets and help the material stay bonded together!

Narrator: It didn’t make a difference.

Attempt #4: The Z Counter Patch Experience

After ordering Z Counter Patch (specifically made for countertops), I decided to solve my mold issues once and for all.

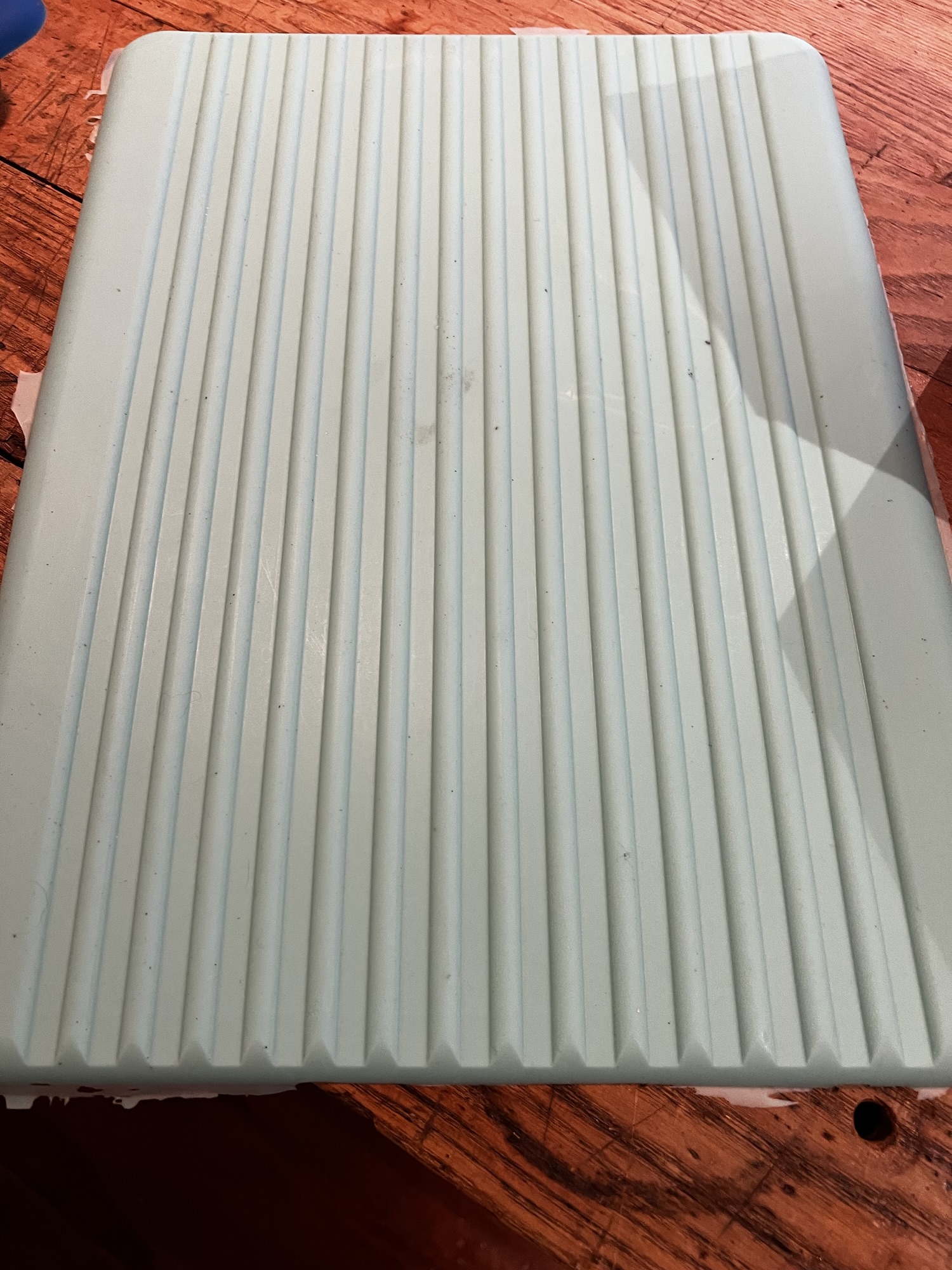

I went back to silicone rubber, ordering Smooth-On Mold Max 60, which was supposed to be harder. It came out true to size but only slightly stiffer than my first silicone attempt.

At this point, I had four molds and a template, none of which were perfect – two rigid and two floppy (one slightly less floppy than the other).

Then it hit me – why not combine them? I could put the silicone mold on the concrete, then the rigid Bondo mold upside down on top of that, with the toe-damaging weight on top of everything.

But wait, there’s more! When we originally poured the countertop, we had a cement vibrator. And wouldn’t you know it, my kids had given me an impact massager for my bad back that could double as a concrete vibrator! I put a plastic bag on the end and vibrated my contraption.

This was going to be AMAZING. I had solved all the issues!

Except I hadn’t. When I lifted the mold, I found the same problem – material stuck to the mold.

Worse yet, the Z Countertop Patch wasn’t durable and didn’t adhere well to the Feather Finish. And when I sanded down the patch, it revealed FOUR different colors of gray. Because apparently, I needed a visual record of every failed attempt.

Attempt #5: The “Mix All The Things” Approach

At this point, I figured if no single product was working, why not mix them all together?

I sifted the Top ‘n Bond through kitchen strainers (don’t tell my wife) to remove the larger aggregate. Then I added some Feather Finish to warm up the gray color and some Z Countertop for smooth sanding properties.

First, I sanded the drain board down as much as possible, which took half a day even with diamond pads and wet sanding.

Then I tried my Goldilocks mixture with the right-sized template that we could make rigid, with pressure and vibration to get it smooth and perfect.

And it was… almost there? I just didn’t use enough material and had some voids. And of course, some concrete still stuck to the template.

Oh, and I broke my Bondo mold by tapping on it with weights while using the vibrator. So I switched to the Alumilite mold.

Where I Stand Now

As I write this, I’m in week three of what should have been a weekend project. I’m making another pass to fill in the voids.

At this point, I’m not sure if I’m fixing a drain board or developing a new concrete formula to rival Roman cement. All I know is that I’m too stubborn to give up now.

Fingers crossed that this try gets me close. Or at least close enough that I can lie to myself about how good it looks.

Stay tuned for the thrilling conclusion. Or my mental breakdown. Whichever comes first.

Follow my DIY disasters at EventThatsOdd.com, where we believe that if it’s worth doing, it’s worth doing with complete disregard for your sanity.

Leave a comment