Or: How Pre-Fabricated Walls Met Our Clay Field

Fall – Winter 2009

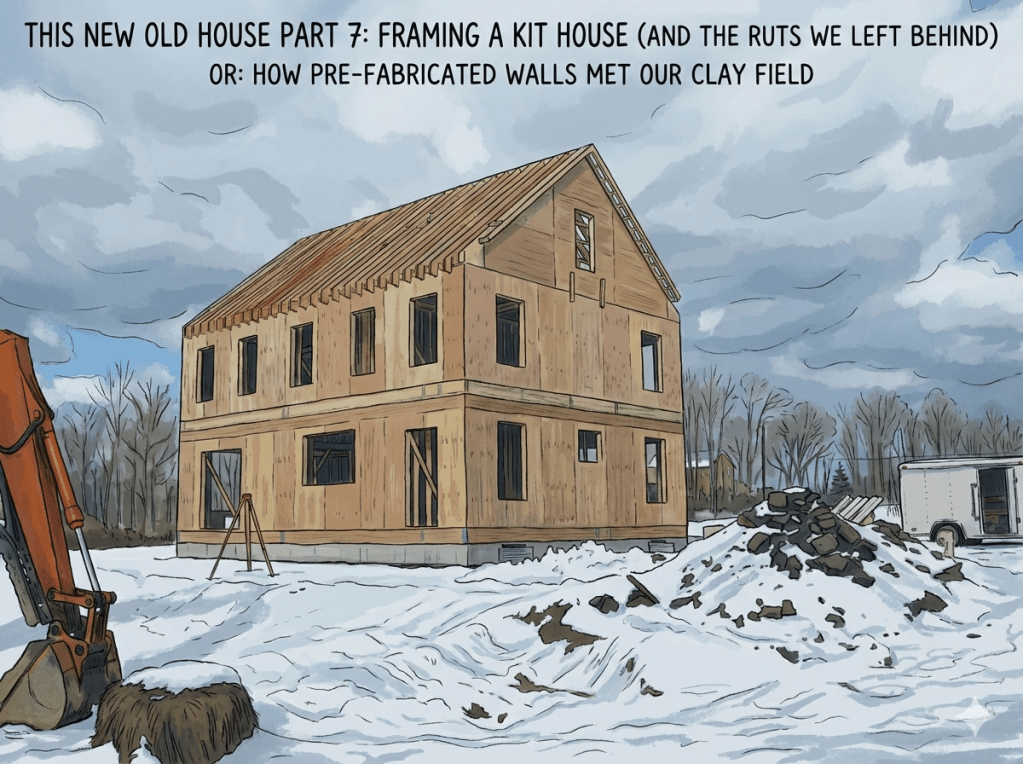

With foundation complete and the Connor Homes kit ready to ship, it was time for framing. This is where our decision to act as our own general contractor would really be tested.

We had a choice: our realtor’s brother was a professional builder who could have managed the entire project. He had experience, established relationships with subs, knew what he was doing. At the time (2008-2009), most contractors were looking for work because of the financial crisis.

In hindsight, maybe hiring a professional GC would have been the smart choice.

But I trusted my friend. One of my better friends, actually—he’s still one of my best friends. He lived nearby and had construction experience. He became our reluctant general contractor, mainly because Jennifer and I were working in the city during the week and he was onsite. Someone needed to be there, and he stepped up.

The Connor Homes Kit Advantage

Here’s the thing about Connor Homes kit houses: most of the wall framing was done in the factory. They provided pre-built and sheathed exterior walls, along with pre-framed interior walls and detailed plans showing exactly how everything fit together.

What the framing crew actually needed to build on-site:

- Floor joists and systems

- Roof rafters

- Roof sheathing

- Assemble the pre-framed interior walls

- Assemble the pre-framed and sheathed exterior walls

The heavy cutting and wall framing had already happened in Vermont under controlled factory conditions. This was one of the major advantages of the kit approach—precision factory work instead of field measurements.

We weren’t super concerned about the framing aspect since it seemed fairly straightforward. The walls were already built. They just needed to be assembled.

The Lull Lift and the Field

The framing contractor needed to rent a Lull lift—a telehandler forklift—to unload the flatbed truck with all the framing panels and materials, then drive them through our field down to the foundation.

The Lull worked great for moving materials.

The Lull did not work great for our saturated clay field.

It was that perfect time of year: pre-ground freezing, but completely saturated. Clay soil + heavy equipment + moisture = disaster.

The Lull put huge ruts in our front field. Deep, wheel-width trenches where the clay just sank under the weight.

This would need to be fixed later. (Spoiler: “later” took a while, and those ruts were visible for quite some time.)

Lesson: If you’re moving heavy equipment across fields in late fall, either wait for the ground to freeze or accept that you’ll be regrading later.

The Framing: Actually a Win

Despite our concerns and inexperience, the framing went well.

The Connor Homes pre-fabricated panels fit together as designed. The detailed plans made assembly relatively straightforward. The framing crew did a really good job putting everything together.

How do we know? Our drywall sub later commented it was one of the straighter houses he had seen. When drywall guys compliment your framing, you know the framers did solid work.

This was actually a win. The factory precision paid off. The framing crew executed well. The house went up straight and true.

What We Asked For (And Didn’t)

We did specify some things:

What we asked for:

- Blocking where the TV would go in the living room

- Easy mounting capability for the TV

- A bit of a built-in area to hide the TV components

What we didn’t ask for:

- Blocking in other places where we knew we’d hang heavy things

- Extra reinforcement in the second-floor laundry room

- Additional blocking throughout the house for future flexibility

The TV mounting area worked out great. We got exactly what we asked for.

Everything else? We didn’t know to ask. It’s not a huge deal, but when you want to hang something heavy, you really should be hitting a stud. That limits placement and creates frustration later.

This is on us for not asking, not on the framers for not reading our minds.

The Joist Reinforcement Issue

The one thing the framers didn’t do great: making sure all the joist reinforcement was properly fastened.

They put the reinforcements in place—the pieces were there, positioned correctly. But then they forgot to go back and make sure everything was actually fastened securely.

This is the kind of detail that gets missed when you’re not checking work in progress. By the time we discovered it, it was past the point of no return. Not a major structural issue, just an annoying detail that should have been done right the first time.

The Structural Support Question

The house was engineered. An architect and engineer both signed off on the structure. Everything met code and professional standards.

There were just a few points that looked like they could have used a little more support. Not failures, not problems—just areas where I thought “that seems like it could be stronger.”

You never know if things get missed sometimes. Engineers are human. Builders are human. It’s better to overbuild than to rebuild.

We added some reinforcement in a few areas that concerned us. Should have been more systematic about it.

The Distance Problem

Looking back, the biggest issue wasn’t the framing quality or the friend helping us. It was communication and distance.

Jennifer and I were working in the city during the week. We’d come up on weekends. By the time we saw things, they were often past the point of no return.

Not major things. Just Jennifer’s and my nitpicky things—the details we cared about that didn’t get communicated clearly enough to the subs.

A professional GC onsite every day would have caught these. My friend, doing his best while juggling his own life, couldn’t catch everything. We, showing up on weekends, saw problems too late.

This wasn’t anyone’s fault. It was the reality of part-time general contracting from a distance.

What We Got Right

- Connor Homes pre-fabricated panels (factory precision paid off)

- Framing crew did excellent work (drywall guy confirmed it)

- Straight, true assembly

- TV mounting area with blocking (we asked, we got it)

- Friend stepped up to coordinate when we needed help

- Saved professional GC fees (10-15% of project cost)

What We Got Wrong

- Didn’t ask for blocking everywhere we’d need it

- No extra laundry room reinforcement (didn’t know to ask)

- Joist reinforcements not fully fastened (should have checked in progress)

- Distance from job site (weekends-only oversight insufficient)

- Didn’t have clear process for communicating nitpicky details

- Assumed “looks good” from a distance meant “perfect” up close

The Reluctant GC Reality

My friend didn’t set out to be our general contractor. He became one by necessity because:

- We were in the city during the week

- Someone needed to be onsite

- He had construction experience

- He lived nearby

- He was willing to help

We hired subs for the work my friend didn’t want to do or couldn’t do. We gave him first refusal on tasks, but he only worked with his nephew—he didn’t have a crew he could bring on. He wasn’t a licensed plumber or other specialized trades, so we needed subs for most of the work.

Electrical was different—he went to school for electrical engineering, so he had the knowledge. He just needed a licensed electrician to inspect the work and sign off on it.

He coordinated, solved problems, made decisions when needed, and did work where it made sense.

But he wasn’t a professional GC with:

- Daily onsite presence as his full-time job

- Experience managing multiple subs simultaneously

- Knowledge of every detail to specify and check

- Systems for tracking and verifying all the little things

The gap between what a reluctant friend-GC can do and what a professional GC does every day is real.

We’re still friends. He’s still one of my best friends. He helped us when we needed it, did work he didn’t plan to do, and got us through the build.

The issues weren’t his fault. They were the inevitable result of part-time, distance oversight by people (us included) who didn’t know all the questions to ask.

What Would Have Actually Worked Better

Looking back at the situation we had, here’s what would have worked:

Option 1: Daily Site Presence

- I should have been able to go to the site every day to inspect what had happened

- Talk to subs directly about progress and details

- Catch issues before they were past the point of no return

- Or even better: be onsite full time during construction

This wasn’t realistic with our work situations, but it’s what would have solved most of our problems.

Option 2: Professional GC

- If daily site presence wasn’t possible (and it wasn’t), hire a professional GC

- Pay the 10-15% fee

- Get someone whose full-time job is being there and managing details

Option 3: What I’d Really Prefer – True Prefab

- Looking back, what I really would prefer is to get this level of detail as a prefab and not just a kit

- The Connor Homes kit put us in-between stick-built and true prefab

- I still love the idea of the Sears Craftsman catalog home

- But I’d want it built inside a factory and just assembled quickly on-site

- Pre-built walls are great, but true modular where entire room sections arrive finished would have been ideal

- Less field work = fewer opportunities for details to go wrong

- Less time on-site = less weather exposure, faster completion

The kit house was better than stick-built for precision, but a fully modular approach would have been even better for our situation.

What We Actually Did (And What We’d Change)

What worked with our approach:

- Saved the GC fee (10-15% of project cost)

- Friend helped when we couldn’t be there

- Connor Homes kit provided factory precision

- We learned a tremendous amount

What didn’t work:

- Weekend-only oversight missed details

- Nitpicky things past point of no return before we saw them

- Couldn’t talk to subs daily to clarify expectations

- Distance from job site created communication gaps

If we couldn’t change our work situation:

- Hire a professional GC – worth every penny for daily oversight

- Or: Choose true modular/prefab with even less field work

- Or: Accept that distance + part-time = compromises on details

If we could change our work situation:

- Take time off to be onsite daily during critical phases

- Talk directly to subs every day

- Inspect work in progress, not just on weekends

- Catch and fix details before they’re covered up

The Lull Lift Ruts: A Metaphor

Those ruts in our front field from the Lull lift? They stuck around for quite a while. Every time we looked at them, they reminded us that heavy equipment on saturated clay makes an impression.

Kind of like trying to general contract a house build from a distance—you leave marks, and fixing them later takes more effort than preventing them would have.

The Long-Term Verdict

Fifteen years later:

- The framing is excellent (thank you, Connor Homes factory precision and competent crew)

- The house is straight and true (drywall guy was right)

- We have blocking where we asked for it (TV area works great)

- We wish we had blocking everywhere else (hanging heavy things is annoying)

- The joist reinforcements that weren’t fully fastened haven’t caused problems (but they should have been done right)

- We’re still friends with our reluctant GC (friendship survived the build)

- Those field ruts eventually got fixed (but we looked at them for months)

This was actually one of our better outcomes. The Connor Homes kit system worked. The framing crew was good. The structure is sound.

The nitpicky details we missed? Those are on us for not knowing to specify them, not on anyone else for not reading our minds.

__________________________________________________

Next up: Part 8 – Electrical: When My Friend Actually Did Read the Code Book

(In which my friend did the electrical work himself, we ran cable everywhere “just in case,” and we discover that over-wiring is one of the few things you can’t do too much of)

__________________________________________________

Quick Takeaways

Kit House Framing:

✅ ADVANTAGES:

- Factory precision (straighter than field framing)

- Most cutting done under controlled conditions

- Detailed assembly plans included

- Less room for field measurement errors

- Faster assembly than stick-built

❌ CHALLENGES:

- Heavy panels need equipment to move

- Lull lifts destroy saturated clay fields

- Still need competent assembly crew

- Floor systems, rafters, roof built on-site

Part-Time Distance GC:

✅ CAN WORK IF:

- You have experienced friend onsite

- Good subs who don’t need oversight

- Simple, straightforward build

- You’re okay with “good enough” details

❌ DOESN’T WORK FOR:

- Catching nitpicky details

- Daily quality oversight

- In-progress inspections

- Projects requiring constant communication

- People with high detail expectations (like us)

Blocking and Reinforcement:

✅ SPECIFY IN ADVANCE:

- Every location for TV mounts

- All areas where heavy items will hang

- Second-floor laundry reinforcement

- Any special load requirements

- More blocking than you think you need

❌ DON’T ASSUME:

- “Standard” means what you think it means

- Framers will add extra blocking without being asked

- Everyone knows to reinforce laundry rooms

- You can add it easily later

Budget Reality:

- Professional GC: 10-15% of project cost

- Friend as reluctant GC: Save the fee, miss some details

- Lull lift rental: $200-400/day

- Fixing field ruts: $500-1,000 later

- Adding blocking after drywall: 10x more expensive

What Actually Matters:

The house is straight, true, and structurally sound. The Connor Homes kit system worked beautifully. The framers did good work.

Missing some blocking? Annoying but not catastrophic. Unfastened joist reinforcements? Should have been checked but hasn’t caused issues. Field ruts? Eventually fixed.

The big things went right. The small things we missed are on us.

Our Grade: B+

Excellent framing quality, good sub work, Connor Homes kit system worked great. Lost points for missed details due to distance/part-time GC, but nothing major. One of our better outcomes.

Final Thought:

Connor Homes’ factory precision saved us from a lot of potential framing problems. The drywall guy’s compliment about how straight the house was tells you everything you need to know—the kit system worked, the framers executed well.

The details we missed weren’t about the framing. They were about us not knowing what to specify when we had the chance.

Also: don’t drive heavy equipment across saturated clay fields unless you enjoy looking at ruts for months.

Leave a comment